Customer: Linamar Role: Vision / Automation Engineer Via: Ascension Automation Solutions Location: Guelph, Ontario Timeline: Aug 2025

The Challenge

A CNC machining line producing gears was experiencing intermittent quality escapes:

- CNC occasionally skips teeth during machining

- Operators can enter wrong dimensions

- Air supply instability leading to inconsistent part positioning

- Manual checks weren’t catching edge cases

Stand-alone vision inspection station integrated into the production cell:

System Design

Designed a robust, PLC-integrated vision inspection system that detects missing or incorrect gear teeth, fits cycle-time constraints, and survives real factory conditions.

Camera, lens, lighting, and trigger strategy tuned specifically for Cell geometry. PLC-synchronized capture was critical — timing mattered a lot here.

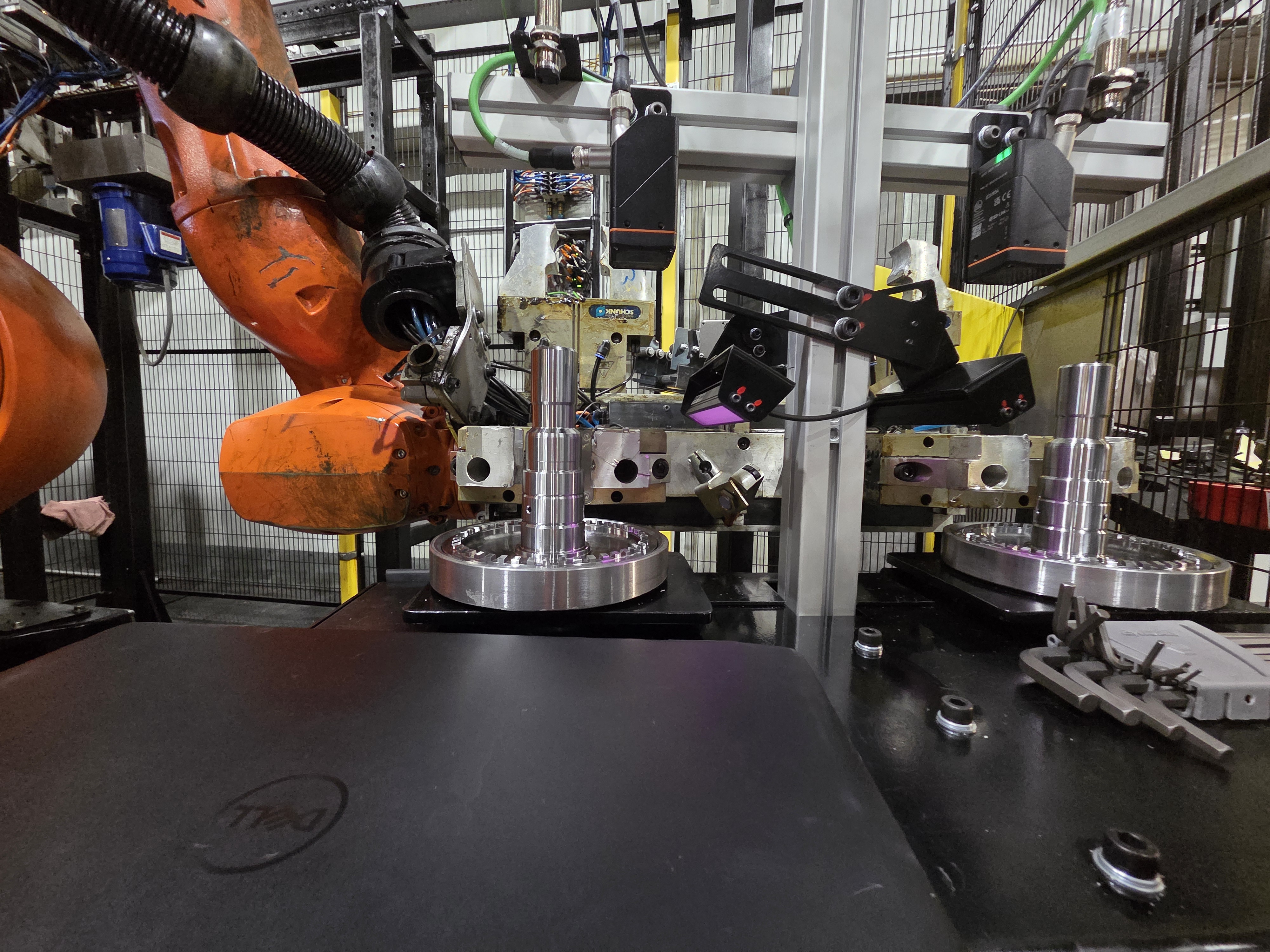

Robot placing part before inspection:

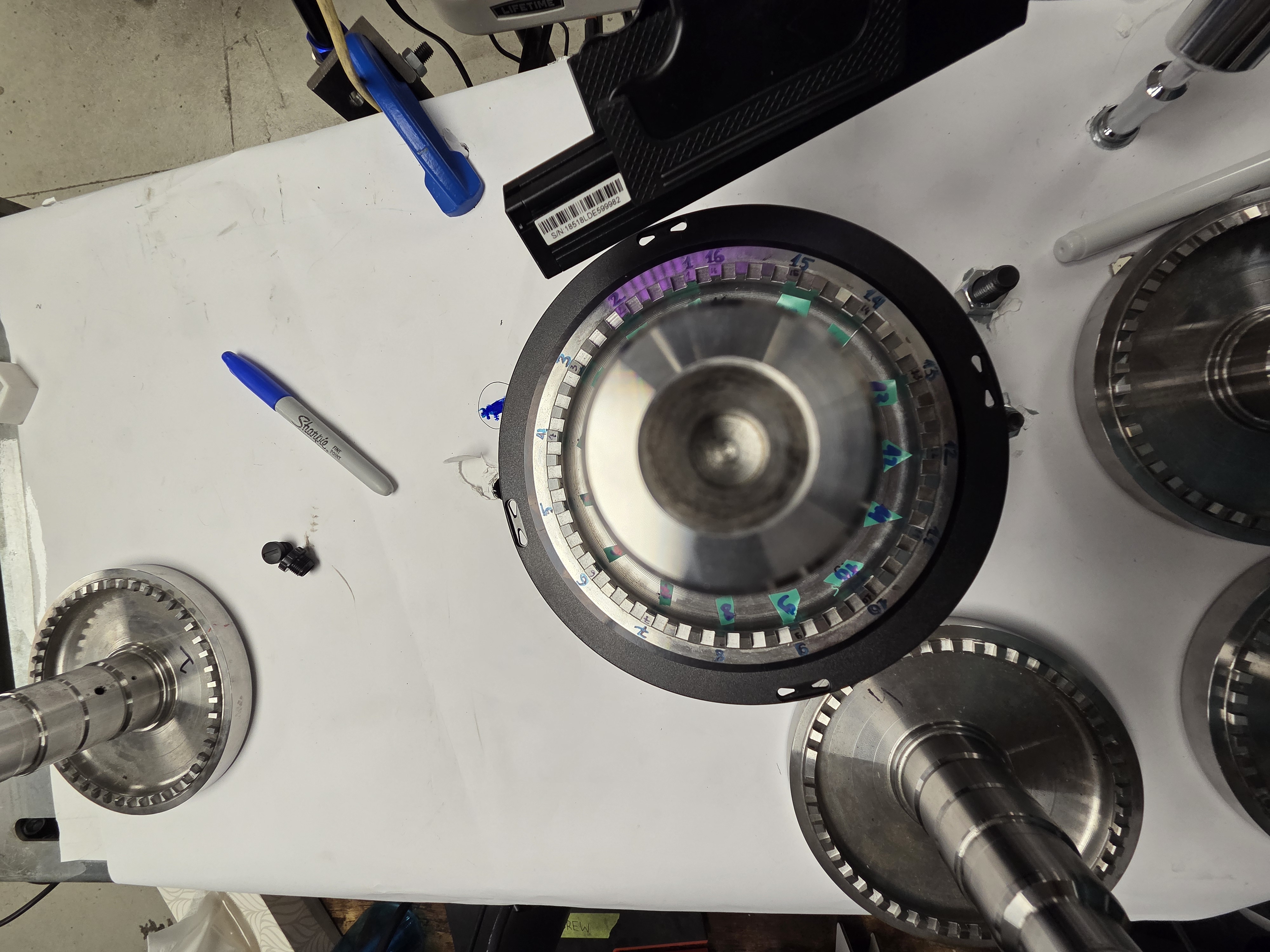

Bench Testing

Built an offline bench test to simulate real-world failure modes:

- Wrong dimension inputs

- Camera and light proof of principle

Validated inspection logic before touching production equipment:

Integration & Commissioning

Key integration work:

- Camera trigger timing optimization

- Vision ↔ PLC Hand handshake coordination

- Kuka robot teach points for part handling

- System validation and fault logging

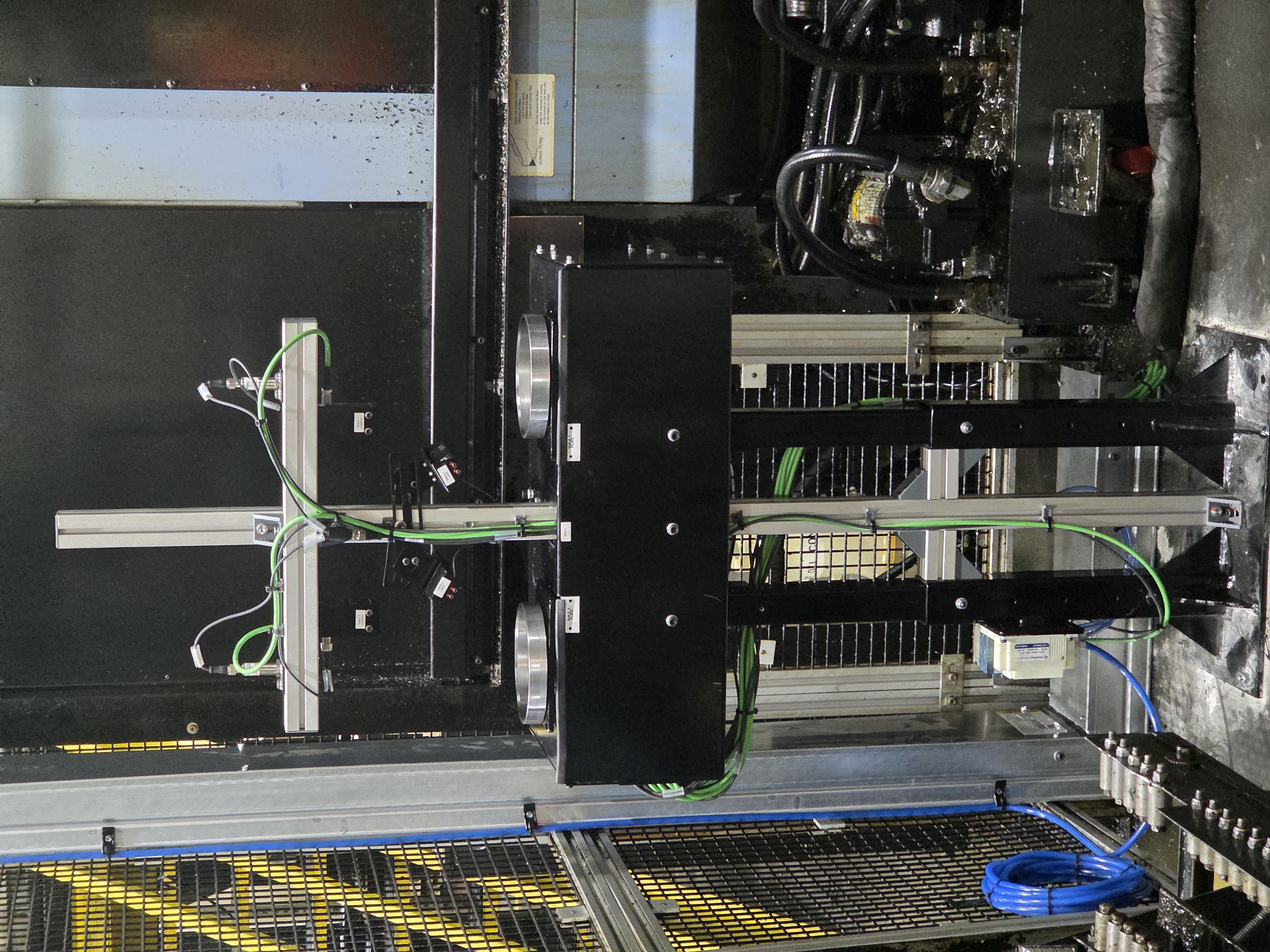

Full inspection station overview:

Results

- Stable detection of missing and incorrect teeth

- Issues caught before parts reached downstream operations

- Smooth commissioning thanks to early bench validation

- Operators gained confidence in automated inspection

Demo Video

Tools and Technologies Employed

- Machine Vision Systems (IFM)

- PLC Integration Siemens

- Kuka Robot Programming

- Bench Test Validation