Customer: General Motors (CAMI) Role: Machine Vision Control Engineer Via: Ascension Automation Solutions Location: Ingersoll Timeline: Aug 2024 – Apr 2025

The Challenge

EV battery production was ramping fast. Vision systems were a bottleneck.

- Low throughput (~5 packs/shift)

- Fragile inspections leading to frequent downtime

- Operator loading errors

- Maintenance slowed by unclear alarms and HMI flows

Part 1: Maintenance & Factory Integration

Supported existing vision systems on the production floor — troubleshooting, optimizing, and connecting systems to factory infrastructure.

Key tasks:

- Debugged and stabilized inspection logic to reduce false rejects over 50 camera program were updated based on previous performance and statistics.

- Improved PLC alarms and HMI workflows for faster fault isolation

- Connected vision systems to plant network and data logging

Part 2: New Inspection Station Delivery

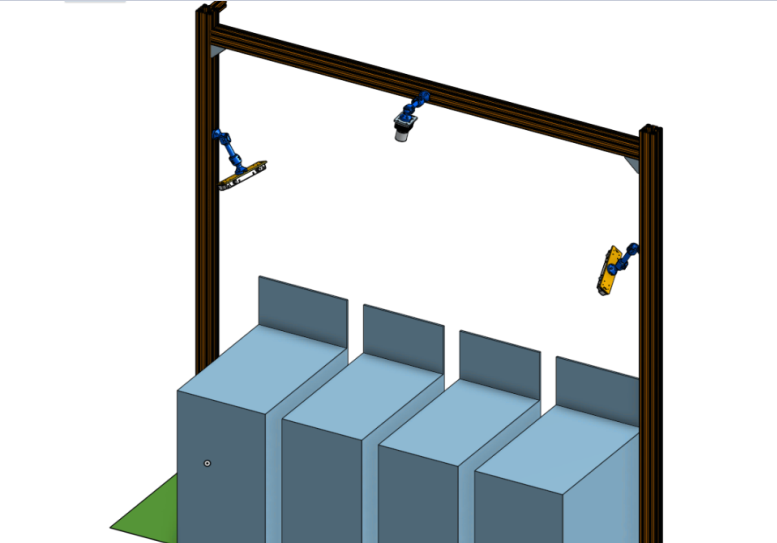

Designed and delivered a complete engineering kit for a new vision inspection station.

Software prototype for inspection application:

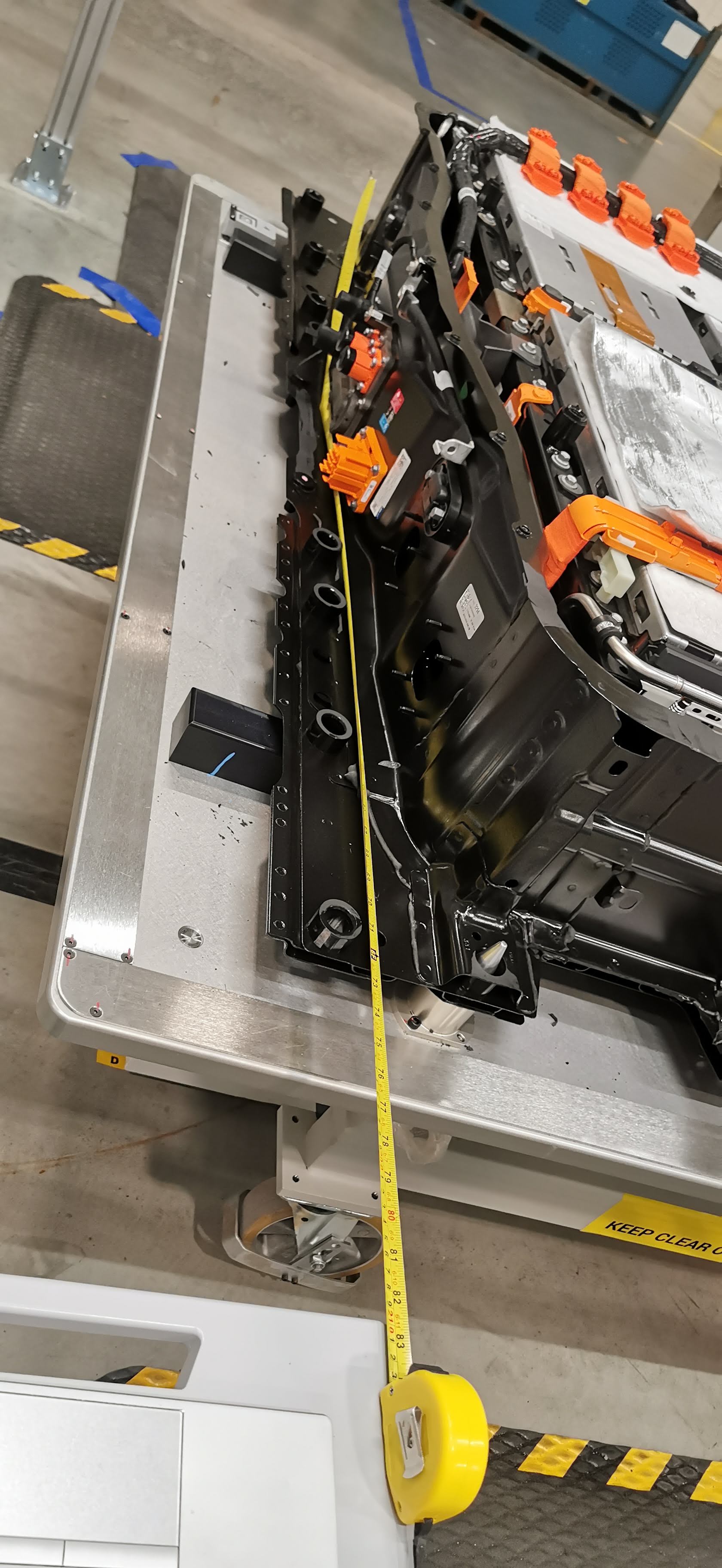

Production validation with parts on test background:

Operator loader station before camera installation:

Design: CAD layout for camera placement, lighting, and cable routing

Kit included:

- Cameras & lenses

- Lighting

- Mechanical fixtures & mounts

- Cables, routing, and accessories

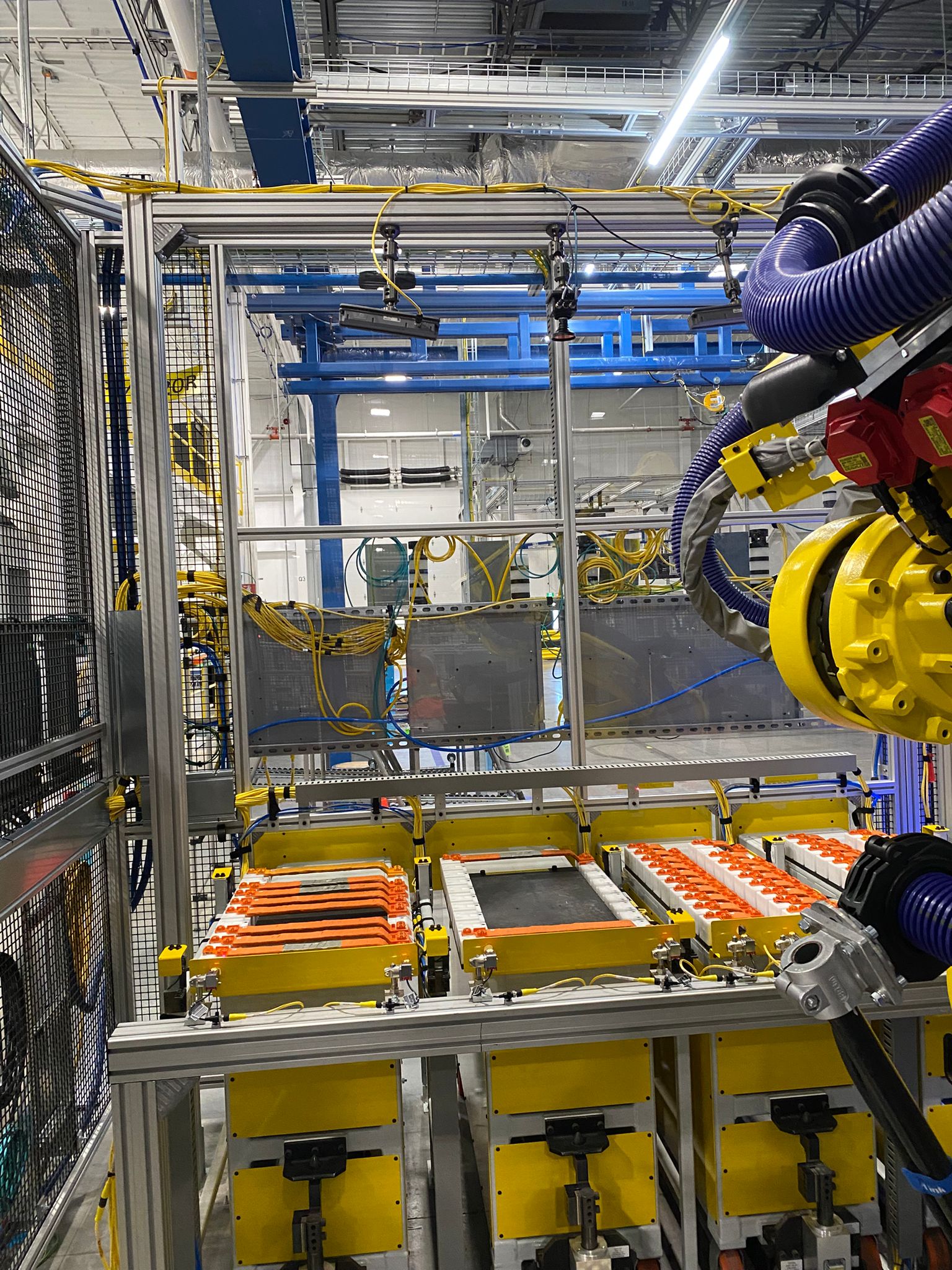

After: Final station installed and running on production floor

Results

- Fewer false stops and recoveries

- Maintenance teams diagnosed issues faster

- Line reliability improved during high-volume production

Tools and Technologies Employed

- Machine Vision Systems

- PLC & HMI Integration

- Engineering Kit Design

- Plant Documentation & Handoff