Customer: General Motors Role: Vision / Automation Engineer Via: Ascension Automation Solutions (contracted to ATS) Location: Ramos Arizpe, Mexico Timeline: Jan – Jul 2024

The Project

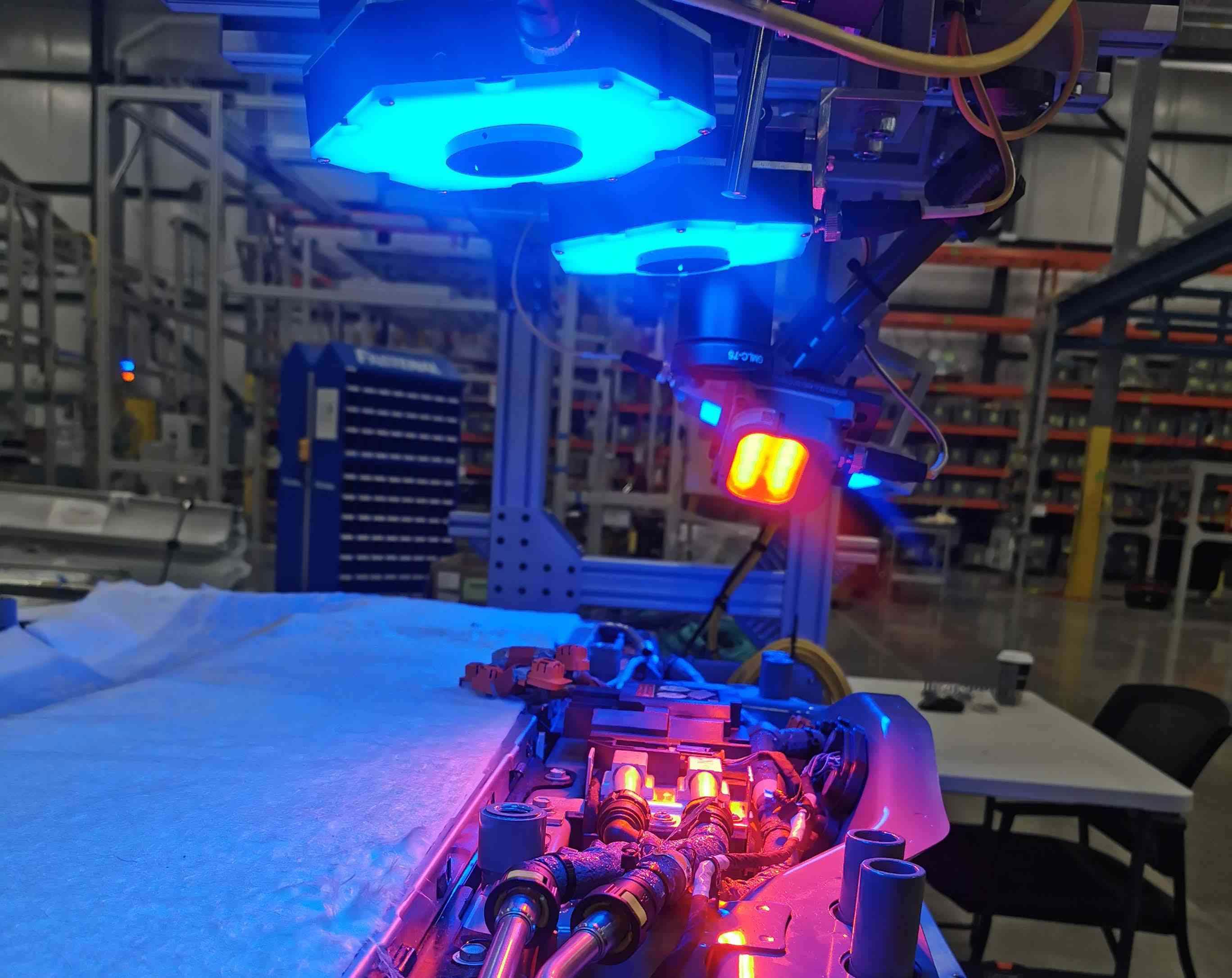

Commissioned error-proofing inspection systems for GM’s EV battery lines. Started at the ATS campus in Cambridge, Ontario for Factory Acceptance Testing, then deployed on-site in Mexico.

Factory Acceptance Test (FAT)

Custom-built and developed the camera system before deployment. Used Matrox cameras with Design Assistant software — a flowchart-based tool for programming inspection logic.

FAT setup validating inspection before shipment:

On-Site Installation

At Ramos Arizpe, Mexico, I oversaw hardware installation and verified delivered parts against ATS design specifications.

Key tasks:

- Supervised mounting and placement of all components

- Directed camera and lighting setup — adjusting angles, focus, and exposure

- Optimized inspection programs using dummy samples from GM

- Programmed web interface for on-the-fly parameter tuning

Troubleshooting

Resolved various field issues:

- Cameras restarting randomly due to power problems

- Inspection images not saving to camera computer

- Unreliable inspections after program updates

Also gained hands-on PLC and HMI experience integrating stack lights, barcode readers, and torque controllers.

Project Phases

Aligned work with plant milestones:

- N1/N5: Initial setup and verification

- N30: Refinement and pre-production prep

- PPAP: Validation to GM quality standards

- Production: Optimization for full automation

Result: 100% automated inspection system with minimal intervention.

Results

- Fully automated vision inspection system deployed

- Met all GM quality standards through PPAP

- Effective collaboration across Ascension, ATS, MTQ4, and GM teams

Tools used during commissioning:

Tools and Technologies Employed

- Matrox Design Assistant

- Keyence IX-Navigator

- Studio 5000 (Allen Bradley PLC)

- Siemens TIA Portal

- Windows Networking