During my tenure at Allied Scientific Pro from September 2019 to October 2021, I had the opportunity to work on several cutting-edge projects that pushed the boundaries of technology.

In this post, I will delve into the problems we addressed, the actions we undertook to resolve them, and the broader impact these solutions had on various industries.

Laser Cleaning System

Problem

Traditional methods of material de-coating are often labor-intensive, time-consuming, and may not be suitable for delicate applications in restoration, aerospace, automotive, and nuclear industries.

Action

i contributed to the mechanical design development of a handheld laser cleaning system that utilizes precise laser beams to target specific distances for de-coating materials.

This innovation revolutionized the way materials are cleaned, providing a faster, more efficient, and delicate process, suitable for various industrial applications and used at Canada’s parliament.

Automating the Laser Cleaning Process

Problem

The manual laser cleaning process was marked by human error and inefficiencies. It required a solution that could add precision and automation to the process.

Action

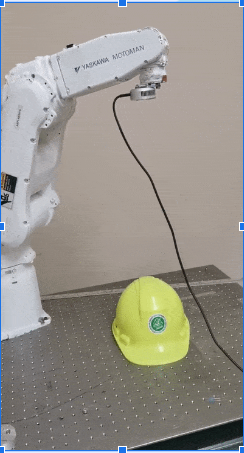

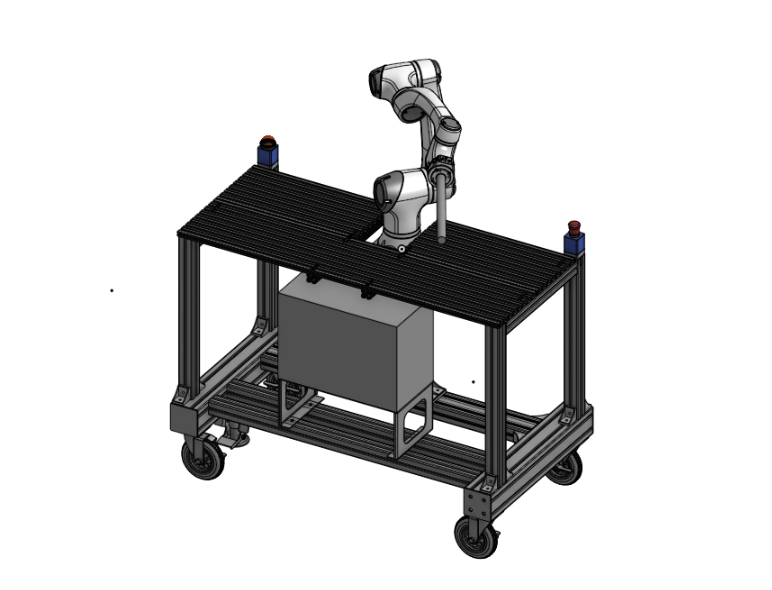

Established automation projects for repetitive labour potential for clients teaching robots such as Yasakawa Motoman and Fanuc.

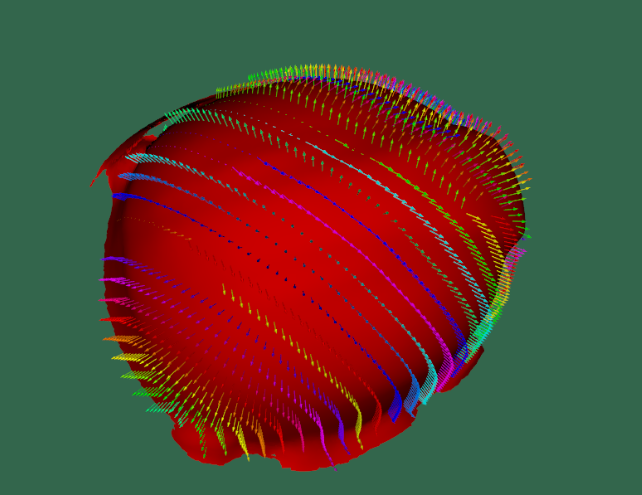

Led the automation R&D Project of automating the laser cleaning process using 3D sensors and a robotic arm. The proof of concept was successful and funded externally, moving to the prototype phase.

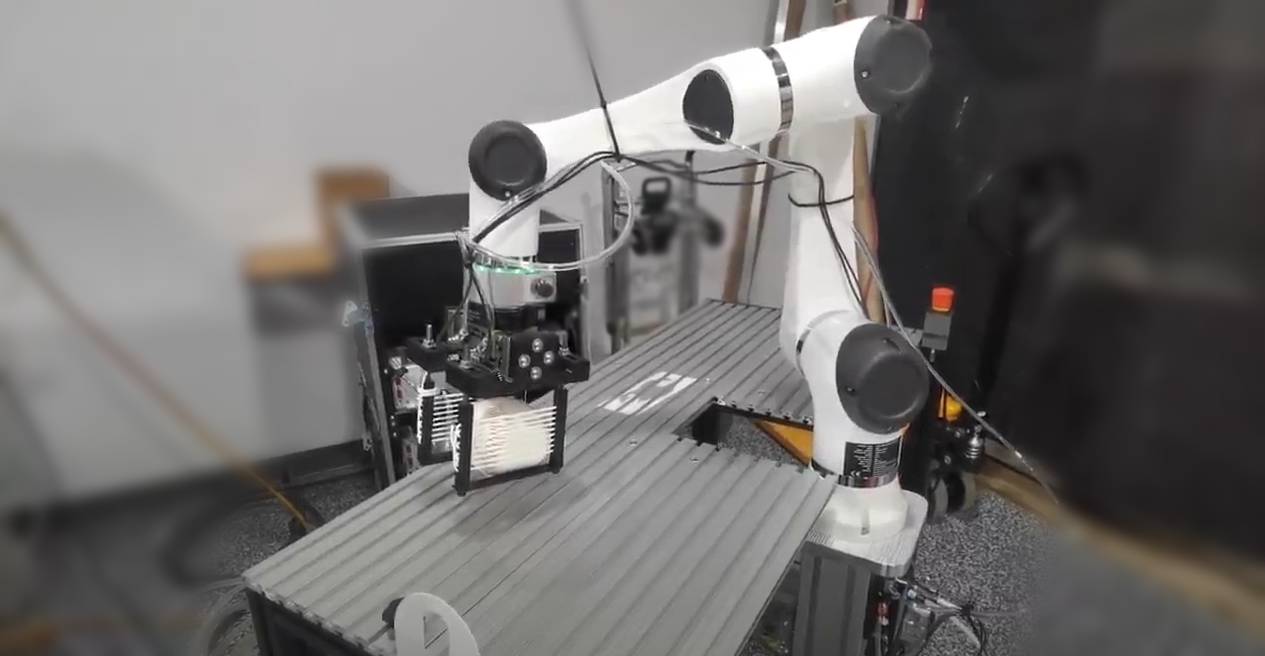

Then I lead the sourcing and installation of a robotic arm, then the integration of Fanuc R-2000ic/210F with moveit. This shows one of the tests I was performing.

Impact

The automated system pushed the boundary of automation, unfortunately I was not there long to witness the end of this potential project.

Other Work

Different tasks for different projects.

Action

- Developed 3D CAD designs, engineering drawings, and BOMs for LCS and robotic arm products.

- Integrated robotic arm and pneumatic systems.

- Designed, implemented, and tested safety systems.

Impact

These projects strengthened our ability to deliver custom solutions to clients. They also helped us develop a better understanding of the challenges faced by various industries and how we can help them overcome these challenges.

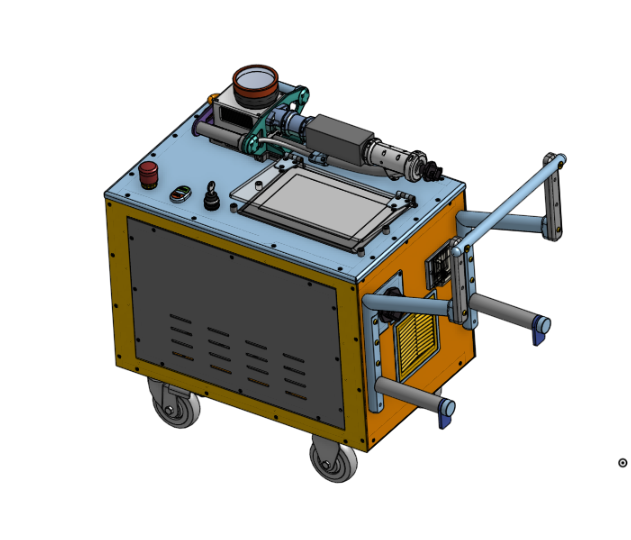

Single Event Effects (SEEs) Testing Station

Problem

The occurrence of single event effects in electronic components can lead to serious performance issues. A specialized system was required to test and mitigate these effects using a laser.

Action

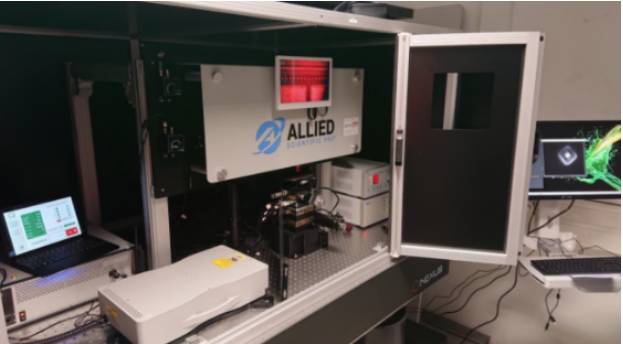

- Managed the project custom work and production to completion.

- Implemented, deployed, and commissioned a specialized testing system for SEEs.

Impact

The development of the SEEs testing station allowed for the robust evaluation and mitigation of single event effects, enhancing the resilience and reliability of electronic systems across various applications.